1L Supercritical CO2 Extraction Machine

This model, 1Liter Supercritical co2 extraction machine, which is customized for supercritical fluid technology research, especially for university and technical institutions, as well as teaching laboratories and precision research.

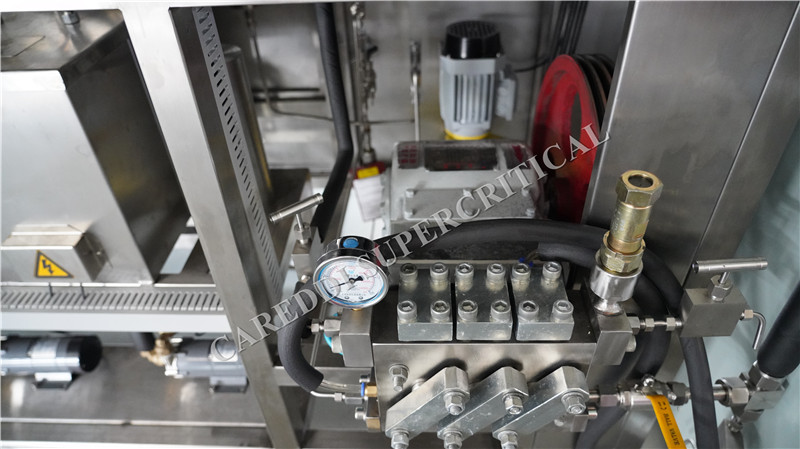

Detailed pictures of 1L Supercritical CO2 Extraction Machine

Main Part list of Model 1Liter (SFE-01L) Supercritical co2 extraction machine

|

Sn. |

Part Description |

Qty(set) |

Made Material |

|

1 |

Extraction

Vessel |

1 |

#304

Stainless steel |

|

2 |

Material Cylinder |

1 |

#304

Stainless steel |

|

3 |

Separation

Vessel |

2 |

#304

Stainless steel |

|

4 |

Pump |

2 |

|

|

5 |

Cooling

System |

1 |

|

|

6 |

Heating

Exchange System |

3 |

#304

Stainless steel |

|

7 |

Purification

System |

1 |

#304

Stainless steel |

|

8 |

CO2

Storage Tank |

1 |

#304

Stainless steel |

|

9 |

Flow rate

Meter |

1 |

|

|

10 |

Temperature

Control System |

4 |

|

|

11 |

Safety

valves |

4 |

|

|

12 |

Over-pressure

gauge |

1 |

|

|

13 |

Control

panel |

1 |

#304

Stainless steel |

|

14 |

Main

machine frame and operation desk |

1 |

#304

Stainless steel |

Main Technical Parameters of 1 Liter (SFE-01L) Supercritical co2 extraction machine

|

MAIN TECHNICAL INDEX |

||

|

Extraction tank |

Material |

Equipped with jacket water circling heating system, temperature

adjustable, equipped with material barrel for both liquid and solid material. |

|

Volume |

1Lx1, |

|

|

Working pressure |

45MPa |

|

|

Separation tank |

Material |

Equipped with jacket water circling heating system, temperature

adjustable |

|

Volume |

0.5L +0.4L |

|

|

Max working pressure |

20MPa |

|

|

CO2 high pressure pump |

Flow Rate (Triple plunger) |

50L/H (adjustable frequency) |

|

Max working Pressure |

50MPa, pumps head with cooling system |

|

|

CO-Solvent pump |

Flow Rate |

0.25-4L/H(adjustable frequency) |

|

Max working Pressure |

20MPa |

|

|

Cooling system |

Cooling Capacity |

10KW (air cooling) |

|

Temperature range |

-5℃~+5℃

(meet process requirement) |

|

|

Heat exchange system |

Type: Φ6/50MPa With circulating water jacket heating system, adjustable temperature |

|

|

Purification system |

Volume |

1L |

|

Max working Pressure |

50MPa |

|

|

CO2 storage tank |

Volume |

4L |

|

Max working Pressure |

16MPa |

|

|

Level meter |

Model |

6.3-63L/H |

|

Digital indicator |

indicate both instant flow rate and accumulation |

|

|

Temperature control system |

Temperature Range |

Room temperature~85℃ adjustable |

|

Accuracy |

±1℃ |

|

|

Safety devices and other components |

Pressure gauge at high pressure pump outlet, overpressure protection. |

|

|

Safety valve at extraction tank, separation tank, distillation column,

Overpressure automatic relief. |

||

|

Pipe lines |

Valves, fittings: DW6 All parts connected with fluid material are made by 1Cr18Ni9Ti Stainless

steel. |

|

|

Total power |

3 Phase, 11Kw |

|

Customer self-provided Items

3 Phase Electricity Power: 11KW

Installation dimension: 2500×2500×1500mm , plus operation space.

CO2 gas: Food grade≥99.5%, single bottle net weight ≥22Kg

Food grade alcohol ≥99.5%

Application of CAREDDI Supercritical co2 extraction system

| Range of Application | Type of Application |

| Pharmaceutical Industry | Extraction of effective contents of Chinese herbs, concentration, refinement and precipitation of raw material drug, separation and refinement of fatty mixtures. Such as: cannabis CBD oil, hops, chili color, frankincense oil, vanilla oil, mint oil, nutmeg oil, agarwood oil, seabuckthorn seeds oil, cinnamon, coconut oil, coffee beans, etc. |

| Foodstuff | Extraction of hops, caffeine removal from coffee berry, extraction of plant, astaxanthin. |

| Cosmetics and Perfumery Industry | Separation and refinement of natural and synthetic perfumeries, dealkalization of tobacco, extraction of raw material cosmetics. |

| Chemical Industry | Separation of hydrocarbon, refinement of organic synthetic raw material, separation of azeotrope, retrieval of raw materials of reaction, dehydration of water soluble powder of organic solution, water oxidation. |

| Others | Superconducting, semiconductor, ceramics, oil washing of petroleum core, enzyme catalytic reaction, preparation of materials, superfine granules, extraction of complex compound, supercritical dyeing technique, supercritical reaction, supercritical coating technique (pharmacy-making). |