Wiped Film Molecular Distillation Explained

Molecular Distillation/Short Path Distillation is a comparatively new separation technology.

It can separate liquid-liquid mixture under temperature that is far lower than boiling point by the difference of mean free path of molecules under high vacuum condition.

Such separation is difficult or unable to achieve on normal distillation equipment. Molecular Distillation is especially suitable to separate substances of high boiling point, heat sensitive and easy oxidized.

Application for Molecular Distillation System

1. Thermal separation of heat sensitive chemical compounds.

2. The purification of organic synthetic material.

3. The separation of effective components from the biological extracting solution.

4. The recycling of industrial waste.

5. Remove toxic substances in the food industry.

6. The organic compounds' decoloring, and eliminate the unusual smell.

7. High precision to remove residual solvent in chemical compound.

Three Stage 2m² Molecular Short Path Distillation equipment

1.The 1st stage: 2m²Wiped film distillation

|

No. |

Designation |

Specification |

Material |

Note |

|

1 |

Feed pump |

0-600L/h |

304 |

Include motor and reducer. |

|

2 |

Evaporator |

2㎡ |

304 |

Include main tank, , wipers, group heating tubes and insulation layer. |

|

3 |

Magnetic seal & magnetic drive |

304 |

Include motor, reducer, magnetic seal and drive. |

|

|

4 |

Condenser |

3㎡x2 |

304 |

Shell-tube type |

|

5 |

Discharge pumps(2 sets) |

0—600L/h |

304 |

Include motor, reducer |

|

6 |

Discharge pumps(2 sets) |

0—300L/h |

304 |

Include motor, reducer |

|

6 |

Buffer tank(heavy component) |

30L |

304 |

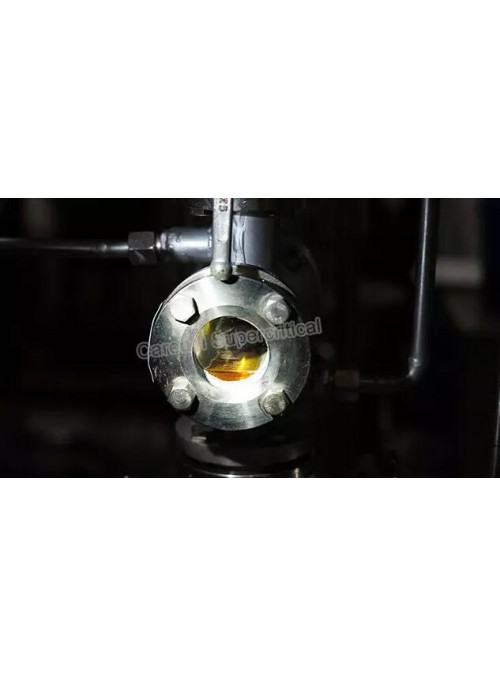

With sight glass |

|

7 |

Buffer tank(light component) |

30L |

304 |

With sight glass |

|

8 |

Vacuum gauge |

Resistance |

||

|

9 |

VVVF(4 sets) |

Brand: ABB For controlling feed and discharge pumps and evaporator. |

||

|

10 |

Pipelines & valves |

304 |

Include connection flange of input and output oil pipeline and sight glass. |

2. The 2nd and 3rd stage: 2m²short path distillation

|

No. |

Designation |

Specification |

Material |

Note |

|

1 |

Short path evaporator |

2㎡ |

304+Q235 |

Include wipers, built-inside 4m² condenser and group heating tubes. (Stainless steel jacket and head); Stainless steel flange |

|

2 |

Magnetic seal & magnetic drive |

304 |

Include motor, reducer, magnetic seal and drive. Explosion-proof motor. |

|

|

3 |

Group Cold trap |

3㎡x2 |

304 |

Shell-tube type |

|

4 |

Buffer tank(heavy component) |

20L |

304 |

With sight glass, thermal jacket

|

|

5 |

Buffer tank(light component) |

20L |

304 |

With sight glass, thermal jacket

|

|

6 |

Discharge pumps(2 sets) |

0—600L/h |

304 |

Include motor, reducer Explosion-proof motor, thermal jacket. |

|

7 |

VVVF(3 sets) |

Brand: ABB For controlling feed and discharge pumps and evaporator. |

||

|

8 |

Vacuum gauge |

Resistance type |

||

|

9 |

Pipelines & valves |

304 |

Include connection flange of input and output oil pipeline and sight glass. All the material pipelines have thermal jacket |

3. Vacuum system

|

Stage |

Designation |

Specification |

Material |

Quantity |

Notes |

|

1st stage |

Oil free vertical vacuum pump |

125 |

1 |

Explosion-proof motor |

|

|

70 Roots pump |

ZJ-70 |

2 |

Explosion-proof motor |

||

|

70 Roots pump |

ZJ-70 |

1 |

Explosion-proof motor |

||

|

Buffer tank |

20L |

304 |

1 |

||

|

Pipeline & valves |

Pipelines & valves are 304, frame is carbon steel |

1 set |

Include frame |

||

|

The 2nd and 3nd stages |

Oil free vertical vacuum pump |

150 |

1 |

Explosion-proof motor |

|

|

150 Roots pump |

ZJ150 |

1 |

Explosion-proof motor |

||

|

300 Roots pump |

ZJ-300 |

1 |

Explosion-proof motor |

||

|

Diffusion pump |

KZ300 |

1 |

Developed by Junge

|

||

|

Buffer tank |

20L |

304 |

1 |

||

|

Pipeline & valves |

Pipelines & valves are 304, frame is carbon steel |

1 set |

Include frame |

||

4. Accessory units

|

No.

|

Designation

|

Specification

|

Material

|

Note

|

|

1 |

Raw material heating tank |

300L |

304 |

To heat raw material. With heating jacket and stir. Explosion-proof motor |

|

2 |

Heating oil furnace (3sets) |

24KW |

Carbon steel

|

One of them is to heat raw material heating tank. The other two are to heat the pre-heater and the 2 evaporators. The heating sticks are explosion-proof. |

|

3 |

Heating oil pump (3sets) |

30L |

Carbon steel

|

The oil pumps are resistant to high temperatures with explosion-proof motors. |

|

4 |

Temperature-regulation oil system |

0.5m³ |

304 |

Include oil tank, heating unit, oil pump and temperature controlling unit. It’s for cooling medium of internal condenser. The system has cooling unit. The cold source is from the refrigerator. |

|

5 |

Cooling system for vacuum and diffusion pump |

0.3m³ |

Include water tank, circulating pump and heating exchanging unit. To cool diffusion pump and the two roots pumps, and the water-ring pump’s cycling water. |

|

|

6 |

Electrical control |

Manual, explosion-proof |

Carbon steel, explosion-proof cabinet |

The explosion-proof cabinet (with AC) includes electrical elements, meters, switches, cables and conduits of equipment area, etc. |

|

7 |

Equipment platform |

Stainless steel

|

Two floors with fences, stairs and platform. The uprights and beams are carbon steel, the fences and stairs are stainless steel. |

|

|

8 |

Chiller System |

-80 C degree |